Join us at Pack Expo Chicago, and learn about sustainability advances in blister packaging!

RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

ProMach offers more than a century of experience in designing, manufacturing, integrating, and supporting the most sophisticated and advanced pharmaceutical and medical packaging solutions in the marketplace. ProMach’s technologies can meet the most challenging requirements with minimal downtime, higher productivity, and true pharmaceutical packaging performance, with compliance built right in.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreHighlights

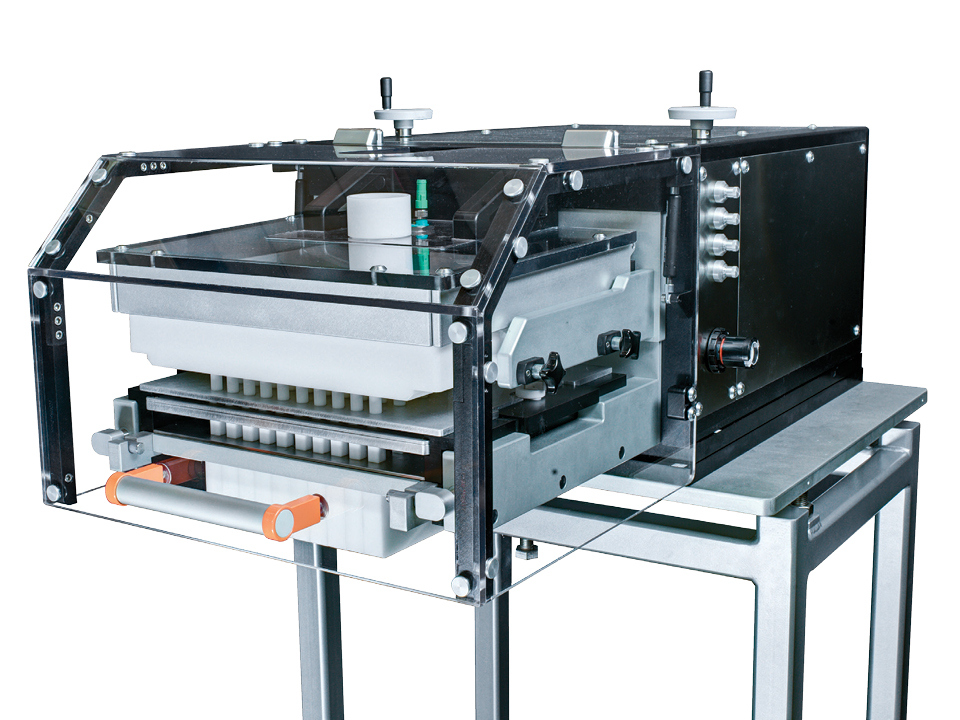

- Speed (Max)80CPM

- Max Feed Area Length (Index)270 mm

- Max Feed Area (Width)170 mm

- Simple and Cost Effective Tooling

- Capable of feeding multiple products simultaneously

- Mobile cart design for accessibility and easy changeover

- Integrate with third party small to medium output blister machines

- Industry standard GMP design

- Full view of entire feeding process for easy troubleshooting and operation

Standard Features

Optional Features

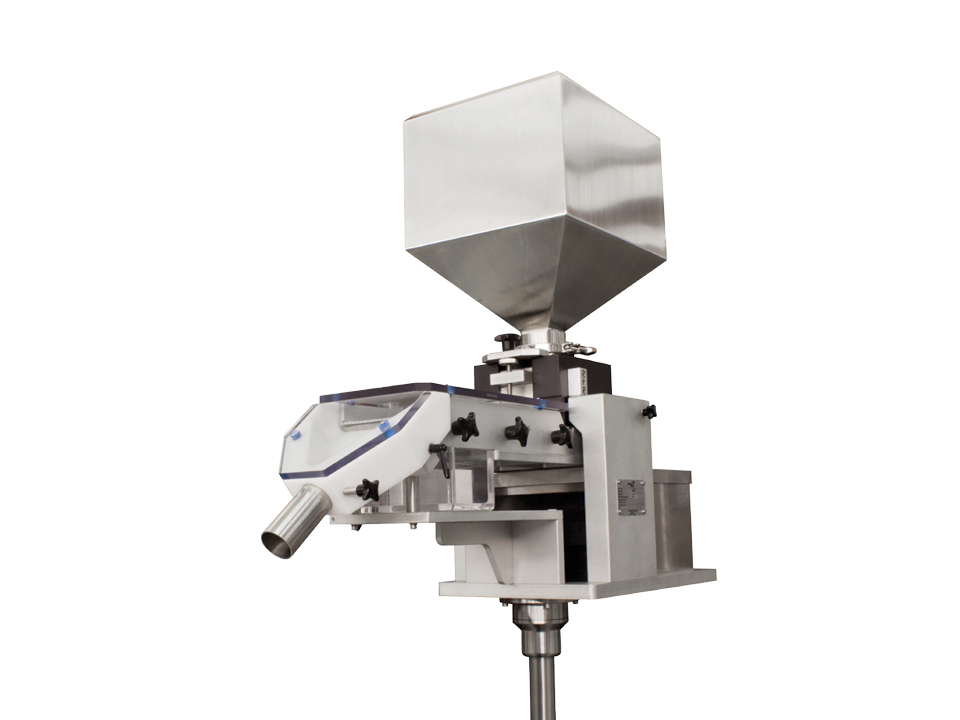

- Dual paddle box and bulk hopper systems for feeding multiple products

- Integrated bulk hopper control

Tooling

- Tool-less change-over

- Tooling is completely tested at Pharmaworks prior to shipping (Pharmaworks is committed to keeping a running TF1e in-house for tool testing)

- A setup and testing sheet is provided with each toolset, reflecting factory-recommended parameters. This is essential for quick and efficient start-up of new tooling

Compatible Bulk Hopper Systems

- Pharmaworks BV1 Bulk Vibratory System

Compatible Thermoformers

- Pharmaworks TF1 Blister Machine

- Pharmaworks TF1e Blister Machine

- Pharmaworks TF1pro Blister Machine

- Integrate with third-party small to medium output blister machines