Join us at Pack Expo Chicago!

RELATED Pharma PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

ProMach offers more than a century of experience in designing, manufacturing, integrating, and supporting the most sophisticated and advanced pharmaceutical and medical packaging solutions in the marketplace. ProMach’s technologies can meet the most challenging requirements with minimal downtime, higher productivity, and true pharmaceutical packaging performance, with compliance built right in.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreHighlights

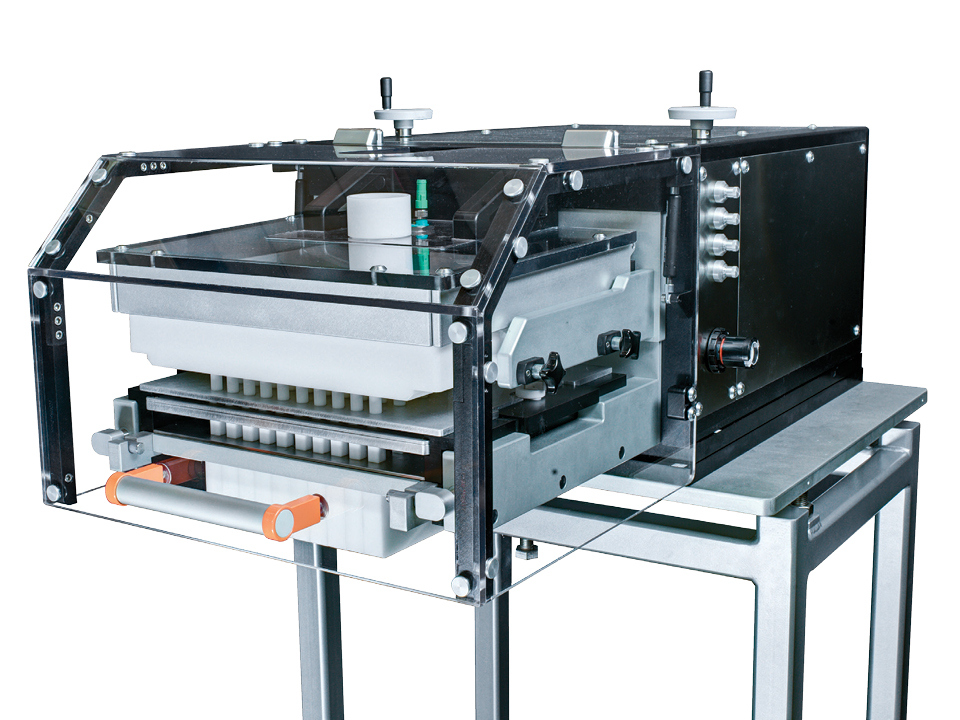

- 2 stirring assemblies and 2 brush assemblies

- Max Web Width 175mm

- Planetary stirring assemblies with independent speed and height settings

- Brushes with independent speed and height settings

- Adjustable flood box product level control

- Mobile cart for easy removal from thermoformer

- Quick lift system for access under feeder for cleaning and maintenance

- Optional bulk vibratory unit integration

Standard Features

- Planetary stirring assemblies with independent speed and height settings

- Brushes with independent speed and height settings

- Includes one set of FDA approved paddles and brushes

- Perforated vacuum plate for dust removal

- Proximity sensor with height adjustment for feed level control

- Mounted on portable cart for quick removal from machine

- Docks to machine for precise alignment and stability

- Lift system to quickly lift feeder from track for cleaning or maintenance

- Integrated bulk hopper control

Optional Features

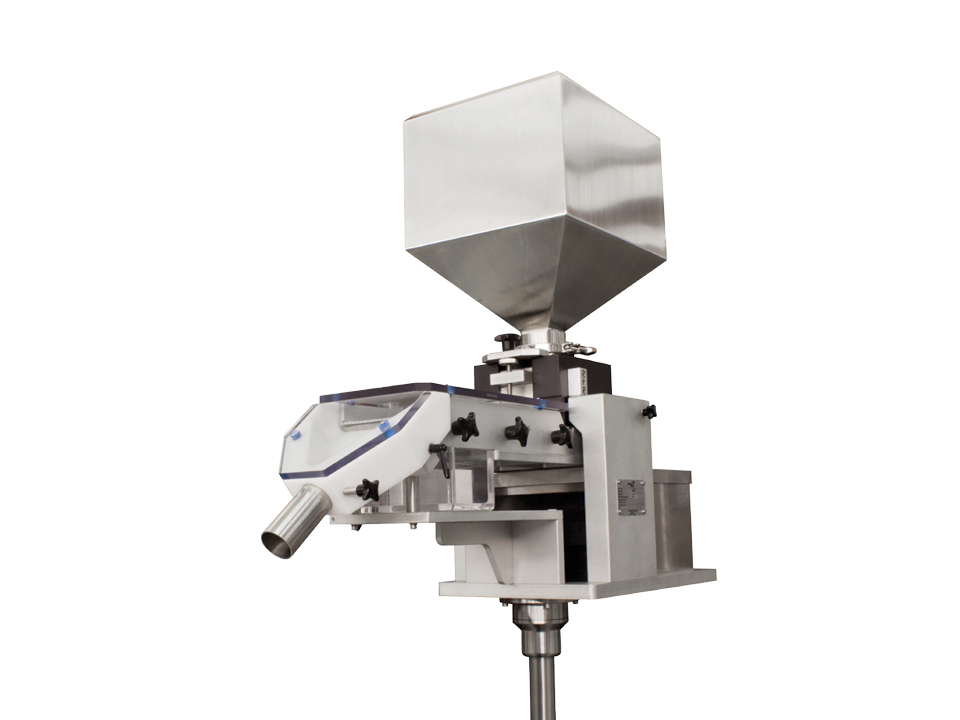

- Bulk vibratory unit can be integrated with the flood feeder system or remain independent

Tooling and Change Parts

- Tool-less change-over

- Paddles and Disc Brush

Compatible Bulk Hopper Systems

Compatible Thermoformers

- Pharmaworks TF1 Thermoformer

- Pharmaworks TF1e Thermoformer

- Third-party systems upon request